Plastic In Cooling Systems

Beginning in the mid-1980's, BMW (and later, Mini Cooper) cars increased the use of plastic in critical areas of the cars' cooling and heating systems. At the same time, operating pressures were increased by 100% over the earlier systems (from 15 to 30 psi), and temperatures by 33% (from 180 degrees to 240 degrees Fahrenheit).

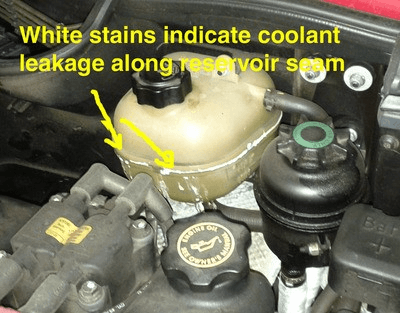

Plastic has the advantages of low cost and weight and an abundant supply of recycled material. Offsetting these qualities are its unpredictable way of failing and poor response to thermal stress over time. In other words, plastic becomes unreliable with age, and it fails unpredictably. To complicate this, plastic often fails, like rubber cooling hoses, from the inside out. In other words, there may be no external indications of aging: no visible cracks; no stains; no visible clues to the deterioration going on inside.

Our job as BMW technicians is to identify and replace failed parts, but also to suggest cost-effective preventive repairs. All too often, a failed plastic part will generate an emergency repair, only to have another plastic part in the cooling system fail soon after. The metaphor we use to describe this is that of an old garden hose: patch the big leak, and watch for the next one to spring up. With cooling systems, this method generates much duplicated labor, inconvenience, and potential engine damage. A more efficient approach is to look ahead and plan when to replace these parts as a group. This approach maintains the car's reliability while reducing the overall cost of repairs.

Our Recommendations

Six Cylinder Models

E36 (92-97) and E34 models (92-95) with six-cylinder engines: replace the o.e. water pump with an all metal unit; replace the radiator no less often than every 100,000 miles. E46models (98-04) and E39 six-cylinder cars have more reliable water pumps, but other plastic parts, including a radiator expansion tank, a plastic electronic thermostat and a top hose with a plastic coupling and bleeder. We recommend replacing all of these, along with the radiator no less frequently than every 10 years or 100,000 miles, whichever comes first.

V-8 Models

All the comments above also apply to the V-8's, but there are two additional areas of concern. These are, first of all, the "valley plate" under the inlet manifold, which takes several hours to access and replace; and it tends to leak in a sneaky fashion, down the back of the engine onto the bell housing of the transmission. Because of the extra cost of accessing the valley plate, V-8 cooling systems cost more than half again as much to overhaul. Secondly, the V-8 electronic thermostats have a habit of leaking coolant at the plug connector into the engine wiring harness and up into the engine management computer. The damage that can result from this is hard to imagine, but real:

We recommend flushing the coolant, as recommended by BMW, every two years. Blue "organic acid technology" coolant ("O.A.T") must be used, and mixed 50/50 with soft or distilled water. Here at H&B, we pressure test the cooling system (including the pressurized filler cap), and check for any recent stains.

It appears that there will be even more plastic in cars of the future, and hopefully of improving quality. In the meantime, we can help the current ones stay reliable by acknowledging and dealing with the limitations of this ubiquitous material.